- Company

- Services

- Products

- Spare Parts

- Logistics

- Training/Classes

- Contact

Long service life for high operational reliability

Established in 1965, STENFLEX® develops, produces and supplies flexible pipe connections to customers throughout the world.

Three features set STENFLEX® expansion joint technology apart:

This means that operators can rely on the expansion joints for cost-effectiveness and sustainability.

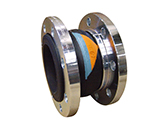

STENFLEX® offers something exceptional in terms of the quality, value and durability of its products. The STENFLEX® brand has become inextricably linked with rubber and steel expansion joints made of traditional materials such as EPDM, NBR, butyl and stainless steel. These provide the optimum conditions for absorbing motion and noise.

Long service life guaranteeing high operational reliability

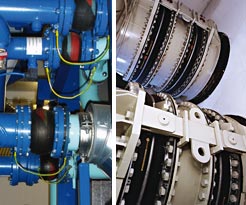

STENFLEX® rubber expansion joints impress with their compensating and damping material properties. Excessive force, arising within the pipeline, is deflected by STENFLEX® rubber expansion joints before this can be passed on to adjacent components. The expertise in designing, and constructing rubber expansion joints, is reflected in the long service life, and high operational reliability. As a result, most European nuclear power plants are equipped with STENFLEX® expansion joints. STENFLEX® pipe connections are made of high-quality rubber. They are used in industrial environments and in plant and process engineering as well as in mechanical engineering, in the production of motors and the construction of industrial equipment, and even in shipbuilding. They have also found their way into building services engineering, environmental engineering and hydraulics.

The company’s product portfolio includes rubber and steel expansion joints, PTFE expansion joints, fabric expansion joints, pipe connectors, hoses, swivel joints and rubber-metal bearing elements.

Eliminate vibration and noise

For high compressive strength and thermal endurance

Resistant to virtually all chemicals and solvents

For stability under pressure with gaseous media at high temperatures

Absorb vibration and intercept sound transmission

Designed to suit assembly conditions, reliable and flexible in any length

Flexible pipe connection elements with high compressive strength and thermal endurance

Full service locations in Southeast, the Gulf Coast, and the Pacific Northwest, plus a network of local representatives throughout the Americas and the Caribbean.

Please complete the form below. Non-Emergency Requests Only.

"*" indicates required fields

Specializing in turnkey engine services, control systems, and engineered solutions for the Marine, Industrial, Energy, and Defense/Government Sectors, MSHS is ready to serve you!