- Company

- Services

- Products

- Spare Parts

- Logistics

- Training/Classes

- Contact

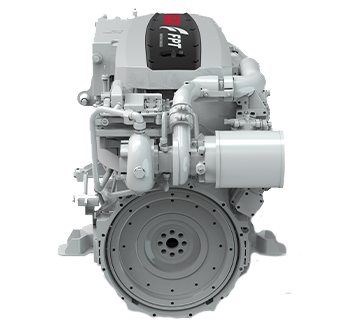

Developed for the most demanding heavy duty needs, the Cursor family provides robust design for highly intensive missions in a wide range of agriculture and construction applications from 175 to 570 kW.

pecifically designed for heavy duty off-road applications, all Cursor engines share 6 cylinder architecture and EGR-free technology, ensuring optimal engine output with efficient combustion, resulting in effective performance and low cooling requirements, unchanged from Stage IIIA to Stage V for smart synergies across machine layouts.

Moreover, all engines meet Stage V regulation with maintenance-free HI-eSCR2 system, the latest generation of FPT’s longstanding experience in after-treatment technology, proven by more than 1 million systems sold to date. No need of filter replacement over lifecycle, together with up to 600 hours oil change interval, minimizes running costs.

No additional complexity thanks to no-EGR architecture, ensuring effective performance High-resistance cylinder head in compacted graphite iron (CGI) and more than 20.000 hours of bench-test specifically dedicated to off-road missions, make the Cursor16 a strong and reliable solution

Full service locations in Southeast, the Gulf Coast, and the Pacific Northwest, plus a network of local representatives throughout the Americas and the Caribbean.

Please complete the form below. Non-Emergency Requests Only.

"*" indicates required fields

Specializing in turnkey engine services, control systems, and engineered solutions for the Marine, Industrial, Energy, and Defense/Government Sectors, MSHS is ready to serve you!